Merck Life Science Partners Bloom to Strengthen African National Quality Control Laboratories

July 30, 2020

Highlights from the “Primary & Secondary Reference Standards for Pharmaceutical Analysis” Webinar.

September 14, 2020Watch Webinar Below

Dear Esteemed visitors & participants,

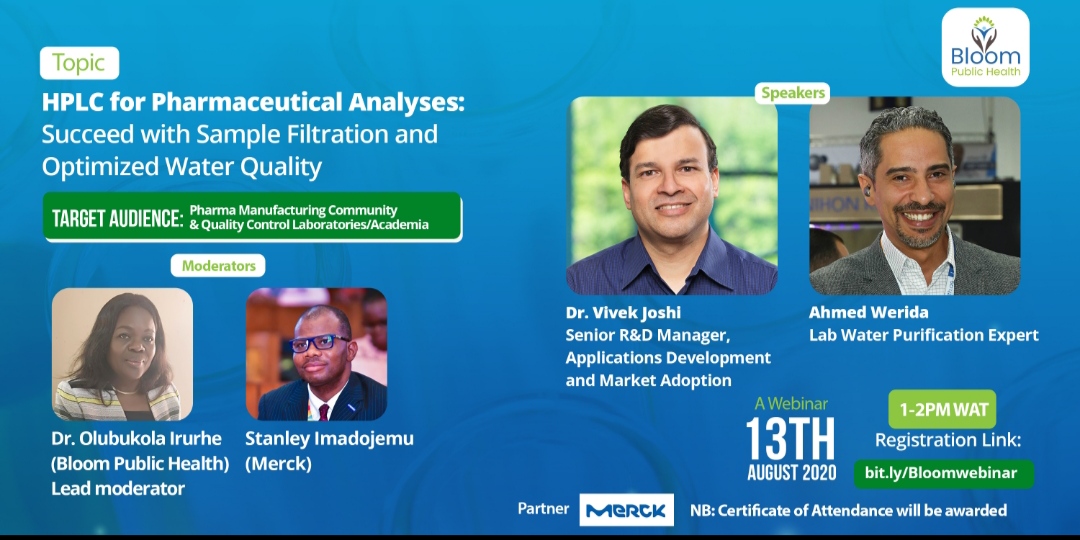

We are pleased to have hosted a webinar titled ‘HPLC for Pharmaceutical Analyses: Succeed with Sample Filtration and Optimized Water Quality’, in partnership with Merck Life Science.

The talking points of the discussion were:

- The importance of sample preparation before HPLC.

- Filtration in pharmaceutical analysis.

- Properties of membrane filters and device.

- Various means of improving throughput.

- Data accuracy and reproducibility: Impact of filtration.

- Introduction on water contaminants and types of purification water, standards and specs.

- Laboratory water types and applications.

- Impact of pure and ultrapure water in HPLC applications and the effect of contamination.

- Merck water purification Solutions.

The Speakers were:

- Dr. Vivek Joshi – Senior R&D Manager, Applications Development and Market Adoption

- Ahmed Werida – Lab Water Purification Expert

Moderated by: Olubukola Irurhe Ph.D. and Stanley Imadojemu.

Questions & Answers

These were the questions asked by the participants and the responses were provided by the speakers.

Q) How can I determine the particle size of the sample before filtration in order to select the appropriate filter?

A) Particle size of sample can be determined by various particle size measurements such as laser light scattering, microscopy, sieving.

Q) Do you have to filter to waste each time you use a filter if using multiple syringe filters due to the sample having high number of particles?

A) If you are concerned about analyte binding / extractables from a filter, then every time filtration is carried out, some amount of sample is filtered to waste to reduce extractables or analyte binding. To reduce sample waste, either HPF Millex syringe filters (syringe filters containing multiple layers of glass fiber pre-filter followed by a membrane (0.2 or 0.45 um)) or syringe filters containing hydrophilic PTFE membrane (which has very low analyte binding and extractables) can be used. Both these methods can minimize the amount of sample filtered to waste before collecting sufficient sample volume for analysis.

Q) Is it possible that the peaks were impurities from the filter membrane and can this problem of contamination from filter membrane be eliminated?

A) It is possible that membranes can contaminate the filtrate (with extractables) which will show up as peaks in chromatography. There are two ways to eliminate extractables,

(i) Flush the syringe filter with sample / solvent (3 – 5 ml)

(ii) Use a syringe filter which has very low extractables (Syringe filters with hydrophilic PTFE membrane).

Q) Why is degassing necessary with ultra pure water before HPLC analyses?

A) You may not need degassing if you are using a freshly prepared ultra pure water from a lab water system. Gases may create some air bubbles that may be stuck in one of the components of a HPLC system like the injector column which creates a high back pressure, or fluctuation of system pressure, resulting in disturbance in the results or even to the retention time expected.

Q) Please can you kindly shed light on how to best determine a suitable solvent for an analyte of interest in a sample product?

A) Suitable solvent for analyte of interest is generally determined by solubility studies with a wide range of solvents. Generally for pharmaceuticals, since these need to dissolve in blood/ plasma, phosphate buffer with pH 7.4 will be considered as surrogate solvent and various salt forms/crystal forms of the analyte will be tested to determine solubility in this solvent.

Q) Is it possible to check the filter membrane for contaminants before use? If there are contaminants on the filter membrane, how is the filter membrane cleaned?

A) Solvent filtration followed by analysis of the filtrate by HPLC will provide information as to whether there are any contaminants (extractables) in the filter. Different solvents may extract different / different levels of extractables from the filter.

Q) I need clarification on which filters are the best. I understand that the nylon is not good enough. I need more clarity on the others.

A) Hydrophilic PTFE membrane based syringe filters have lowest analyte binding and extractables. They are also compatible with organic solutions as well as aqueous solutions. So these are considered to be best choice when working with small molecular weight analytes. For proteins and peptide analysis, hydrophilic PVDF membrane is better with its low protein binding and extractables.

Q) Is there any experimental methodology to determine Analyte binding to filter media and Extractable from filter media?

A) Simple way to measure analyte binding and extractables is by filtration of sample solution through the syringe filter and collecting various fractions of filtrate collected (1st, 2nd, 3rd etc.). These filtrate fractions are analyzed by HPLC for both presence of contaminants (extractables) and analyte binding.

Q) What are possible solutions when available water in the building is of very poor quality? Are there systems with reservoirs that allow water to be added from a better source?

A) In such cases, feed water to labs should be split from the building main water ring by a sub-piping loop feeding a central water purification system, please contact our (Merck) lab water specialist in your country who will support you to design your pure water user specification requirements in term of number of user points, water quality for each point & daily consumption. This will protect your instruments using water inside the labs as well as grant good applications results outcome.

Q) Why do we still have deep water peak while using ultrapure water in HPLC analysis?

A) Ultra pure water is very dynamic solvent that interacts will all types of contamination inside the lab, Deep peak may happen due to one of the contamination effect, It is recommended always to use freshly prepared ultra pure water.

Q) If we centrifuge the high particulate matter, can we still filter using the appropriate filter?

A) Filtration is better than centrifugation, particles only settle down at the bottom of the tube, but when sample is withdrawn from such a suspension care needs to be taken to ensure that particles from the bottom are not picked up by the pipette tip. Filtration on the other hand, remove particles physically from the sample thereby cleaning the sample.

Q) Which of the above mentioned membrane filter is suitable for type 2 water sample?

A) Hydrophilic PTFE membrane based syringe filters have lowest analyte binding and extractables. They are also compatible with organic solutions as well as aqueous solutions. So these are considered to be best choice when working with small molecular weight.

Q) Viruses are smaller than bacteria, why use bacteria in standardizing the pore size rather than viruses?

A) Bacteria are only used in standardising pore size of microporous filters (0.1 – 10 um), whereas viruses can be used for standardizing pore size of ultra filtration membranes (1 – 100 nm). Generally for HPLC application, microporous membranes are used for filtration and their pore size can be determined using bacteria.

Q) What is the difference between Demineralized water, Deionized water?

A) There are no differences they are all commercial names , Please check the slide number 5. It defines water qualities standards, Type I, II & III are the most common names to differentiate.

Q) Is it advisable to use filter a particular twice?

A) It is generally not recommended to reuse a filter since it can contaminate the sample with previous sample that was filtered?

Q) Si la phase mobile est constituée uniquement d’une solution organique, est – il necessaire la filtrer avant utilisation?

A) Purely organic solvents right out of the original bottle don’t need to be filtered (since these are filtered and packed), but when mixing two or more solvents to create a mixed mobile phase, it is best to filter these solvents.

Q) What is the difference between pure water and ultrapure water?

A) Refer to presentation slide 6, pure & ultra pure water may be referring to Type II & Type I qualities respectively.

Q) Are there specifications as regard the type of bacteria permissible in purified water?

A) There are millions of Bacteria types but referring to pure water it should be less than 10CFU/10ml and for ultra pure type I should be less than 1CFU/10ml, Please check slide 6 in the presentation.

Q) Some low budget end user would rather buy non sterile syringe filters and then autoclave hence are non sterile syringe filters autoclave-able?

A) Depending on membrane type and housing material, some non-sterile syringe filters can be autoclaved (Hydrophilic PTFE membrane or PVDF membrane and Polypropylene or Polyethylene housing), but sterility of these filters is not guaranteed. For sterile filtration (for example cell culture), its best to use pre-sterilized syringe filters which are individually packed.

Q) Aside from the extractables you mentioned for different brand of filters, are there other quality test you can perform for especially PTFE Filters to ascertain its quality?

A) You can test for extractables as well as particle retention tests (using latex particle suspensions) to compare different filters. Bubble point can also be measured to provide idea about pore size of different filters.

Q) Is the quality of water for HPLC and LC-MS/MS, the same?

A) They are almost the same, requiring Type I water, but for LC-MS/MS we recommend to use the LC pak containing C18 silica for ultra-trace LC-MS analyses, Please check slide number 14.

Q) Analysis of chemical reference standards using distilled water (2.0uS/cm) has given me a good chromatogram with a single peak void of impurities peaks, is the ultra pure water still useful. And how can we obtain the ultra pure water?

A) Distilled water is not granting a consistent water quality as it is always under the risk of recontamination, ultra pure water will support your result with consistency & even more it’s saving energy & waste of feed water resources knowing the fact that to cool one liter of distilled water you are wasting 15 liter of tap water & 30 L for double distillation

Q) Due to the problem of analyte binding, do we have to search and obtain information about analyte binding before choosing a filter? Is there a rule to the game especially for multi-component drugs with different physicochemical properties?

A) Generally membranes which have large number of functional groups tend to show high levels of analyte binding (Nylon, Mixed cellulose esters, glass fiber etc.) whereas membranes with low number of functional groups (hydrophilic PTFE, PVDF etc.) tend to show low analyte binding. But it is still important to do analyte binding study during method development as analyte binding is also dependent on concentration of analyte, solution in which analyte is present and presence of any other competing analytes (in a multi-component formulation).

Q) What is the implication of resistivity levels in water, it is easier to relate with TOC, CFU etc but of what importance is resistivity to water users especially when a lab is interested in procuring a purification system?

A) Resistivity & conductivity are the most common measurement defines water quality and it represents level of inorganic ions in the water that can impact the instrument performance as well as Formation of adduct peaks if Na+ or K+ are present (concern for LC-MS) , TOC & CFU are also important as it has an major impact on the results as well as instrument performance.

Q) Apart from water what are the other causes of back pressure in a HPLC system?

A) Presence of particles in sample or mobile phase as well as matrix components in the sample (proteins, lipids etc.) can all cause high back pressure in the HPLC system.

Q) What is the impart of reverse osmosis in filtration of water?

A) RO membrane is removing 95-98% of tap water impurities that is enough to produce type III water, however the RO performance is linked to the Tap feed water quality & RO recovery.